The Boeing Company is the biggest aviation manufacturer in the world, and it's valued at more than $209 billion. With more than 141,000 employees worldwide, Boeing builds a commercial plane every 11 hours. Boeing even plans to send humans to Mars on the back of 207,000 Corvettes worth of raw thrusting power. With all that production, Boeing needs one of the largest, most reliable supply networks in the world.

To streamline its supply chain integration with The Boeing Company, BaoTi chose CData Arc to implement an EDI process that could easily integrate with BaoTi's existing IT infrastructure.

BaoTi is a Core Part of Boeing's Supply Network

Located in the heart of Titanium Valley, BaoTi Group is a powerhouse producer of titanium and titanium alloys. Founded in 1965, BaoTi produces more than 40 percent of its entire nation's titanium-based materials and is the nation's largest R&D base for rare metals. Its unique, end-to-end supply chain runs deep into the Earth, as its supply chain encompasses mining titanium sponge materials, smelting, processing & deep processing, equipment design & manufacturing, and worldwide distribution. In addition to its titanium-based supply chain, companies worldwide rely on BaoTi Group for:

- Zirconium

- Tantalum

- And special, rare-Earth metals

Today, BaoTi has earned its place as a key supplier to the aerospace industry, including the US manufacturer Boeing, by delivering core materials for manufacturing processes.

The Challenge: Supplier-Side Economics and The Boeing Raw Material Strategy

Boeing's supply chain spans thousands of vendors across the globe and involves millions of messages, purchase orders, shipments, invoices, and other transactions. Boeing needs a gargantuan IT infrastructure, and, in today's global, Just-In-Time manufacturing economy, that IT infrastructure must deliver instant, seamless connectivity with Boeing's supply chain while minimizing time spent onboarding vendors.

Boeing undertook the Boeing Raw Material Strategy (BRMS), which is an initiative designed to overhaul and streamline Boeing's deep ocean of purchasing transactions, data, and technology.

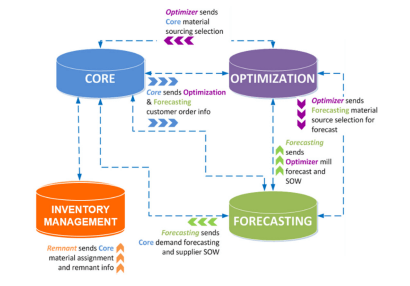

As part of the BRMS, the aviation giant has invested in a key piece of technology: its Raw Material Aggregation System (RMAS), which simplifies its purchases of raw materials, including BaoTi's titanium. The RMAS spans a set of integrated systems that manage the acquisition and distribution of Boeing's raw material supply chain to minimize delivery costs. The RMAS contains four key parts:

- Core Enterprise Resource Planning (ERP) software system that handles order fulfillment

- Forecasting

- Optimization

- Inventory Management

The diagram below shows how these key components interact. When taken together, Boeing's strategy and RMAS have had major ramifications for BaoTi, which needed to align its technology and supply chain with Boeing's ERP to grow its crucial customer relationship.

The Solution: Standardizing with an Electronic Data Interchange

To streamline its supply chain integration with Boeing, BaoTi sought to integrate its electronic order and fulfillment processing with Boeing's electronic data interchange (EDI) system.

So BaoTi chose CData Arc to implement an EDI process that could easily integrate with BaoTi's existing IT infrastructure.

Since its release in 2004, the CData Arc platform has been adopted by numerous system integrators, independent software vendors, and large enterprises to rapidly develop EDI solutions at low cost. CData Arc silently powers tens of thousands of supply chain systems behind the scenes.

BaoTi uses CData Arc to securely send and receive Boeing EDI X12 purchase orders, messages, and acknowledgments. The best part? BaoTi's team can use basic spreadsheets to do it, and no programming or manual translation is required. CData Arc ensures BaoTi can efficiently interface with Boeing's EDI to meet Boeing's standards for world-class suppliers.

Integration with Boeing

BaoTi uses CData Arc for secure file transfer (via an AS2 Connector), EDI messaging, and spreadsheet integration.

Secure File Transfer

Boeing requires suppliers to communicate via an SFTP Connector. The CData Arc SFTP Connector is configured to securely send and receive documents directly with Boeing. In addition to offering the highest security and responsiveness, direct integration eliminates the need for costly VAN processing. BaoTi uses our SFTP Connector for secure file transfer, and it uses the X12 Connector and the Script/Excel Connector for integration.

EDI Messaging

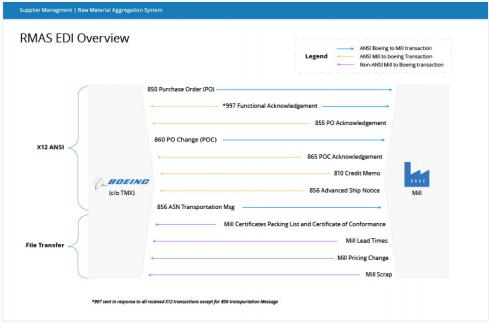

For order processing and fulfillment, Boeing requires BaoTi to communicate through a number of standard EDI messages. Boeing uses the DataToXMLI X12 Connector of CData Arc to transform data between spreadsheet values and EDI standards, as illustrated by this diagram:

CData Arc provides BaoTi an easy way to create Excel-based reports from EDI Files through CData Arc connectors. BaoTi uses the X12 Connector to transform data between EDI and standard XML. Then, using the Excel Connector, BaoTi can transform data from standard XML to easy-to-read spreadsheets. Last, Boeing uses the Email Send Connector to send a spreadsheet to BaoTi's email address, seamlessly receiving human-usable Excel spreadsheets right in BaoTi's inbox.

To communicate updates to Boeing, BaoTi's team can simply manage an Excel spreadsheet with product information. CData Arc monitors the Excel files for changes, and any updates trigger CData Arc to convert new data to (DatatoXML) X12 Connector and pass the EDI documents directly to Boeing.

Tapping the Network of CData Arc EDI Integration Partners

BaoTi selected KA Software, which is an CData Arc featured EDI integration partner, to assist with mapping, translating and configuring AS2. Working with KA Software allowed BaoTi to rapidly accelerate its integration with Boeing, and it also provided BaoTi an expert resource for future expansion.

The Result

Using CData Arc, BaoTi is now more efficient in its order processing and has seamless integration with Boeing. BaoTi was able to transform its existing IT assets into a modern interface for direct, bidirectional communication with Boeing. This was done without in-house development or third-party management. By interfacing directly with the Boeing EDI, BaoTi also gains increased visibility into demand forecasts and improves operational efficiency by reducing order touch time, status updates, and shipping paperwork. Today, BaoTi's relationship with Boeing is thriving, and BaoTi has become a key partner in the Boeing Raw Materials Strategy.